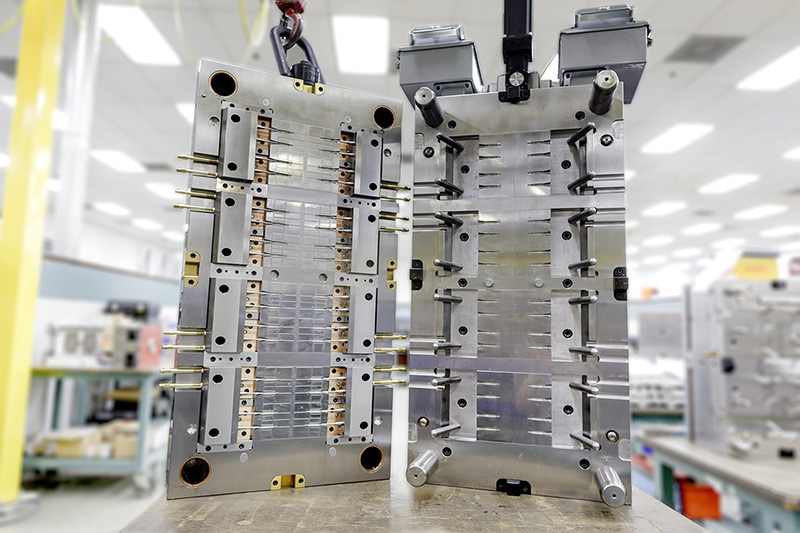

Efficient multicavity processing of small medical parts

There’s a big incentive for molders of small medical parts to increase production efficiency by going to 16, 32, or even more cavities using hot runner/valve gate systems. Molders have always had great success with Eastman Tritan™ copolyester for medium-to-large components of medical devices and electronic instruments. Recently, our commitment to small, multicavity solutions began delivering big results.

- Read more about Efficient multicavity processing of small medical parts

- Log in or register to post comments

Proper cooling saves time, improves quality

With any polymer, poor and uneven cooling can result in:

• Increased cycle time

• High levels of residual stress

• Increased warpage

• Sticking and difficulty in ejection

Considering the unique properties of Eastman Tritan™ copolyester, a few important guidelines will improve efficiency and part performance.

- Read more about Proper cooling saves time, improves quality

- Log in or register to post comments

Designing for Manufacturability Webinar Tomorrow!

The Tritan experts at Eastman are hosting a live webinar on December 10, 2015, from 11:00 to 12:00 EST. This webinar will cover these important considerations to help you design for manufacturability:

- Read more about Designing for Manufacturability Webinar Tomorrow!

- Log in or register to post comments

Tooling design – keys to success

•Select a compatible gating style for the selected resin. Most conventional cold gating styles work well with copolyesters. For hot runner systems, valve gates should be used.

Design Tooling with good Cooling/Thermal Control

•Copolyesters require good thermal control throughout the cavity for optimal processing.

Design Tooling with a plan for venting

•Poor venting can result in burn marks and incomplete fill.

Design Tooling with a plan for ejection

•Parts should be adequately supported during ejection to avoid part deformation/breakage

Click here for more successful processing tips

- Read more about Tooling design – keys to success

- Log in or register to post comments

Close

Close