Early collaboration pays long-term rewards

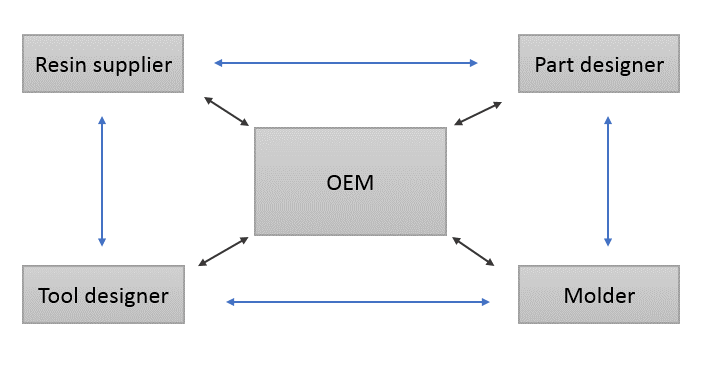

You can increase the chances of success in injection molding projects with early involvement of all major stakeholders. The many rewards of early collaboration include:

- Reduced product development time

- Optimized part performance

- Optimized cycle time

- Lower scrap rate

- Read more about Early collaboration pays long-term rewards

- Log in or register to post comments

Join us at Molding 2016

Eastman will be presenting and exhibiting. Molding 2016 is the premier conference focused on innovations in injection molding technology—with information you can’t find anywhere else. That makes it the perfect place to show and tell the unique advantages of Eastman Tritan™ copolyester.

Join the Tritan experts Mar. 29 to 31, 2016, to learn how Tritan can improve your processes and end products.

- Read more about Join us at Molding 2016

- Log in or register to post comments

Why devices are failing in oncology drug delivery applications

Some traditional polymers used in drug delivery devices are not compatible with modern oncology chemotherapies—including the cancer drugs and the carrier solvents that help make them effective.

Device manufacturers have more reasons than ever to understand the chemical resistance of the materials they use in devices, including:

• The widespread use and growing economic importance of oncology drugs

• A recent FDA Safety Alert* concerning infusion devices made with polycarbonate (PC) or acrylonitrile-butadiene-styrene (ABS)

- Read more about Why devices are failing in oncology drug delivery applications

- Log in or register to post comments

Tritan for medical-device applications

Expect a balance of important advantages with Eastman Tritan™ copolyester MX711.

- Processability

- Chemical resistance

- Toughness

- Hydrolytic stability

- Compatibility with sterilization methods

- Clarity

- BPA-free

- Secondary operations and assembly

- Heat resistance

Eastman Tritan™ copolyester MX711 is well-suited for medical-device applications that demand superior chemical resistance, clarity and hydrolytic stability, including:

- IV system components

- Blood therapy devices

- Read more about Tritan for medical-device applications

- Log in or register to post comments

Pages

- « first

- ‹ previous

- 1

- 2

- 3

- 4

Close

Close