Troubleshooting focus: warped or distorted parts

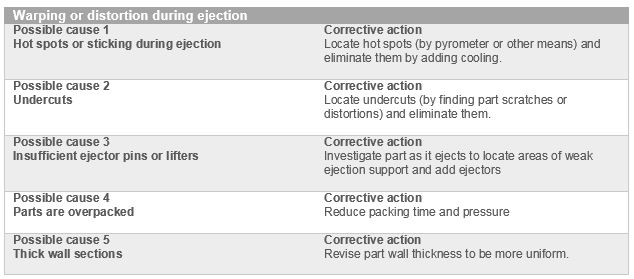

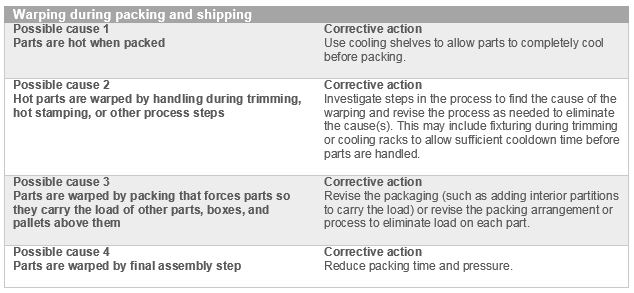

Warping or distortion beyond specification can occur to parts as they are ejected from the mold or after packing and shipping. The final defects can look similar, but their causes are very different.

If you have more questions about warped or distorted parts, talk with your Eastman technical service representative—and ask how to receive a free copy of our Injection Molding Troubleshooting Guide.

| TMI TIP: Proper cooling is well worth the wait when processing copolyesters. Their relatively low flexural modulus gives them a greater ability to flex and rebound—and allowing the skin to freeze is the best way to ensure optimum results. For more information, watch the webinar Copolyester Processing Solutions. |

If you have more questions about warped or distorted parts, talk with your Eastman technical service representative—and ask how to receive a free copy of our Injection Molding Troubleshooting Guide.

Close

Close